posted here because i only want at least semi serious ppl to read it and comment on it. that rules out half or more of the normal 1g community who bought their gt for a grand as a cheap car

when i say proper, i mean air injected into the exhaust manifold while running the engine very rich off throttle and at low pressures such that the fuel ignites as the extra o2 is introduced.

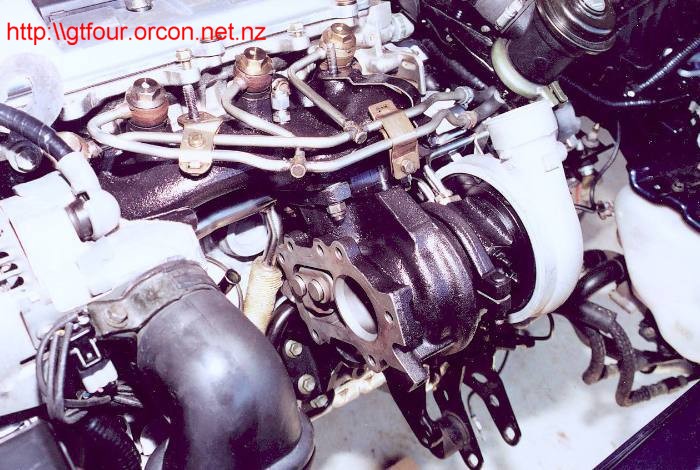

toyota had the makings of this on the celicas (rc versions of the gt4)

here are some pics :

![Image]()

![Image]()

that doesnt appear to use venturis, and thus must somehow rely on pressure to feed the exhaust.

i was hoping that by making venturi tubes and welding them into the runners of my mani i could use check vavles close to the mani and a pwm valve further away to supply air that would not get blown in, but rather sucked in in the same way as evos pcv system (please link that here?)

with a bit of custom ms code, a tps/map/rpm table could be made that supplied the turbo with enough flames to keep it spinning fast enough to boost all the time even if its not as much as when its up and hauling

obviously i have this in mind as an (highly desirable) alternative to downsizing my turbo to a small bb vf34 or something. it would likely be less effort also.

i have read that ppl use controlled bovs to provide the air feed to the valves from a pressurised source (turbo feeds itself bypassing the engine). this could work without the bov being shut once i relocate the bovs to the throttle side of the IC such that there is some back pressure right next to the compressor. but i dunno how effective it would be. it might be that its good at maintaining boost once you have the sucker spooled, and no good at generating it from the get go.

holding pressure in a reservoir is not a goer as it would be consumed far too quickly.

seems like a good way to test the welding on my manifold ;-)

the holset will be up to it i'm sure, and if not, i can get another...

i might have missed some bits n bobs somewhere.

what i want to discuss is the mechanics of getting the air in and the control strategies of making it happen via the ecu.

i might cross post this on hmt and ms forums depending on how poorly i get responses from this one.

fred.

when i say proper, i mean air injected into the exhaust manifold while running the engine very rich off throttle and at low pressures such that the fuel ignites as the extra o2 is introduced.

toyota had the makings of this on the celicas (rc versions of the gt4)

here are some pics :

that doesnt appear to use venturis, and thus must somehow rely on pressure to feed the exhaust.

i was hoping that by making venturi tubes and welding them into the runners of my mani i could use check vavles close to the mani and a pwm valve further away to supply air that would not get blown in, but rather sucked in in the same way as evos pcv system (please link that here?)

with a bit of custom ms code, a tps/map/rpm table could be made that supplied the turbo with enough flames to keep it spinning fast enough to boost all the time even if its not as much as when its up and hauling

obviously i have this in mind as an (highly desirable) alternative to downsizing my turbo to a small bb vf34 or something. it would likely be less effort also.

i have read that ppl use controlled bovs to provide the air feed to the valves from a pressurised source (turbo feeds itself bypassing the engine). this could work without the bov being shut once i relocate the bovs to the throttle side of the IC such that there is some back pressure right next to the compressor. but i dunno how effective it would be. it might be that its good at maintaining boost once you have the sucker spooled, and no good at generating it from the get go.

holding pressure in a reservoir is not a goer as it would be consumed far too quickly.

seems like a good way to test the welding on my manifold ;-)

the holset will be up to it i'm sure, and if not, i can get another...

i might have missed some bits n bobs somewhere.

what i want to discuss is the mechanics of getting the air in and the control strategies of making it happen via the ecu.

i might cross post this on hmt and ms forums depending on how poorly i get responses from this one.

fred.